For applications with high required forces (and therefore very high inflating pressure), Pronal offers 7 bars inflating pressure bags

Made from rubber coated fabric and vulcanized under vacuum in an autoclave, the Pronal HP bags could be inflated up to 7 bar while remaining relatively thin (18mm). The vulcanization process makes the final product homogeneous and guarantees a long lifetime. (more than 10 years in some cases)

Technical information

- UV resistance

- Ozone resistance

In option, Pronal can propose:

- FDA rubber coating

- EPDM coating

- High resistance temperature coating (up to 140°C)

- Dimensions restrictions:

- Square models : 2500 * 2500 mm

- Rectangular models : 5500 * 2500

- Circular models : Ø 2500 mm

Because of the assembly process, a “dead area” (= no inflation zone) will be located all around the bag. This dead area has to be deducted from the surface of the bag before calculation of the applicable force.

Inflation:

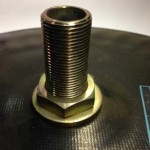

Threaded Inflation stems position 1/4″ ou 3/4″

Schrader Valve

The inflation stem can be placed on the face or the edge. If on the edge, a short tube of copper with a quick connect coupler at the end will be provided; or an integrated steel insert where a stem will be mounted.

Note : The inflation stem located on the edge will increase the “dead area” dimensions.

Miscellaneous:

Maintaining Velcro

Threaded insert

Additionnal surface coating

Pronal can manufacture several bag shapes such as:

Cubical

Circular

Parallelepiped

Cylindrical

3D doughnut

Flat doughnut

Max 3 stages (K1 = square 1 stage / K2 = square 2 stages/ K3 = square 3 stages …)

Other shapes upon request.

- Lifting bag tensioner

- To lift and move a load

- To maintain parts during a vulcanization process

- Tipping over a bucket

- Clamping complex shaped parts